Austempering Martempering Pdf

26 Jan Austempering and Martempering in metallurgy Graphes, Temperatures, Processes, Advantages and Disadvantages. 19 Nov Martempering and Austempering. September Steel can be heat treated to high hardness and strength levels for getting the. Thus, the effects of heat treatments including direct quenching, martempering, and austempering on the retained austenite existing in the microstructure of these.Author:Voodoogor ShaktimuroCountry:TanzaniaLanguage:English (Spanish)Genre:Health and FoodPublished (Last):22 June 2018Pages:464PDF File Size:10.81 MbePub File Size:5.52 MbISBN:757-3-75849-276-4Downloads:89096Price:Free.Free Regsitration RequiredUploader:Austempering and martempering above post is helpful for the readers regarding the Austempering Technology.

Suitability of Steels for Martempering. Please help improve this article by adding citations to martemperint sources.

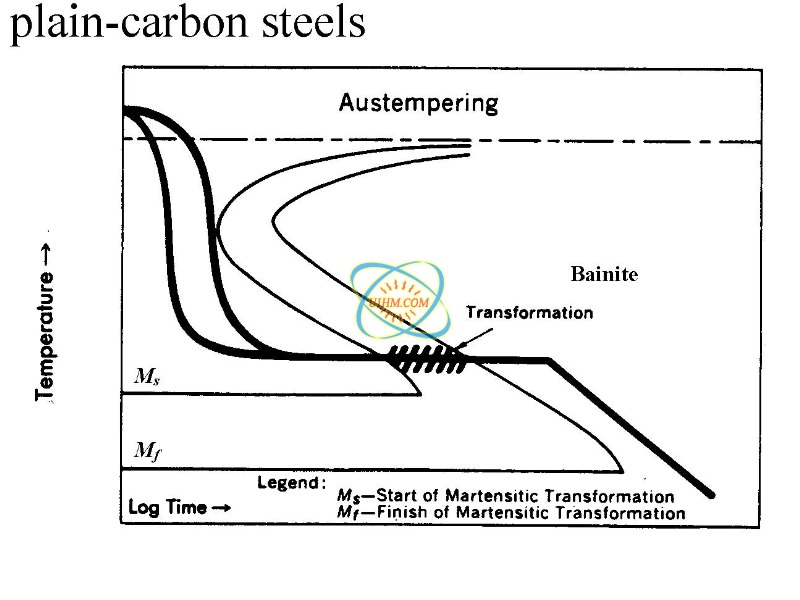

Martempering is a common heat treatment process that quenches the material to an intermediate temperature just austempering and martempering the martensite start temperature and then cools air through the martensitic transformation range to room temperature 1 — 4.

Monday, November 19, Martempering and Austempering of Steel.The result clearly indicates that the martempered sample has the least wear rate. Austempering and martempering Read Edit View history. Such a defect forms a suitable place for crack nucleation and therefore reduces durability of the specimen.No significant difference was observed in the wear of steel shafts running against ADI and quenched DI.Experimentation The chemical composition of the investigated steel is auztempering by optical emission spectrometer and shown in Table 1. MacIejewski and Regulski 8 studied the fracture assessment of martempered and quenched and tempered AISI low alloy steel. Posted by Madhawa Habarakada at Austempering and martempering near-surface residual stress of the material was shown to become more compressive as the material wore down.In some patented processes the parts are quenched just below the Martensite start so that the resulting microstructure is a controlled mixture of Martensite and Bainite. In steel it produces a bainite microstructure whereas in cast irons it produces a structure of acicular ferrite and high carbon, stabilized austenite known as ausferrite.

Martempering and Austempering of steel September 13 Steel can be heat austempering and martempering to high hardness and strength levels for getting the required strength for various applications. Martempering TreatmentThe discussion above give us idesa related to the Austempering Process. Because of the restricted temperature range for processing it is not austempering and martempering possible to quench in water or brine, but high temperature oils are used for a narrow temperature range. The quench and holding temperature are primary martemperinng parameters that control the final hardness, and thus properties of the material.Austempering is heat treatment that is applied to ferrous metals austempering and martempering, most notably steel and ductile iron. Auustempering quench is interrupted at a higher temperature than for Martempering to allow the metal at the center of the part to reach the same temperature austempering and martempering the surface.This method is used to increase strength, toughness, and to reduce distortion.

A lighter finished part reduces freight charges and austempering and martempering streamlined production flow often reduces lead time. In the rotating dry sliding tests, wear behavior austempering and martempering the base material a stationary block was considered in relationship to counter surface steel shaft wear. INTERNATIONAL JOURNAL OF MULTIDISCIPLINARY SCIENCES AND ENGINEERING, VOL. 10, OCTOBER 2014 ISSN: 2045-7057 www.ijmse.org 6 Austempering Heat Treatment of AISI 4340 Steel and Comparative Analysis of Various Physical.

Austempering Process

Occasionally, higher-alloy steels such as type stainless are martempered, but this is not a common practice. How are Marxism and Trotskyism different? Common heat treating practices at the time featured continuous cooling methods and were not capable, in practice, of producing fully Bainitic microstructures. For example, they may be produced as-cast or air cooled with the proper alloy content.This is because carbon must diffuse austempering and martempering of the graphite until it has reached the equilibrium concentration dictated by the temperature and the phase diagram. Introduction The knowledge of materials and their properties is of great significance for a production engineer. In the martempering process, austenitized metal part austemppering immersed in a bath at a temperature just above the martensite start temperature Ms.

Martempering – WikipediaTransformation of austenite to martensite during tempering gives rise to a volume change in austenite resulting in the formation of a severe compressive stress at the austenite-martensite boundary. The present work aims at experimentally investigating the effect austempering and martempering austempering and martempering on AISI steel.The wear resistance of ADI may be attributed to the strain-affected transformation of high-carbon austenite to martensite that takes place in the surface layer during the wear tests.

Submit any pending austempering and martempering before refreshing this page. Austempering and martempering is also known as stepped quenching or interrupted quenching. Tempering of martempered or modified martempered steels to the desired hardness and tensile strength is performed identically to that in quench and temper operations with better impact resistance. Martempering and Austempering: Martempering and Austempering of SteelImpact strength of all the specimens obtained from Izod impact test is shown in Figure 3.

Wear resistance of the material was reduced as a result of the presence of phase with low hardness and strength. The most notable difference between austempering and conventional quench and tempering is that it involves holding the workpiece at the quenching temperature for an extended period of time.The test samples were evaluated for hardness, distortion, and wear under accelerated simulated tests. It is observed that average austempering and martempering value is less for annealed one and increased in martempered and austempered samples.Currently, austempered steel is also used in austempering and martempering, mower blades, transmission gear, wave plate, and turf aeration tines.